Take you into the world of AB glue machine

2021-02-01

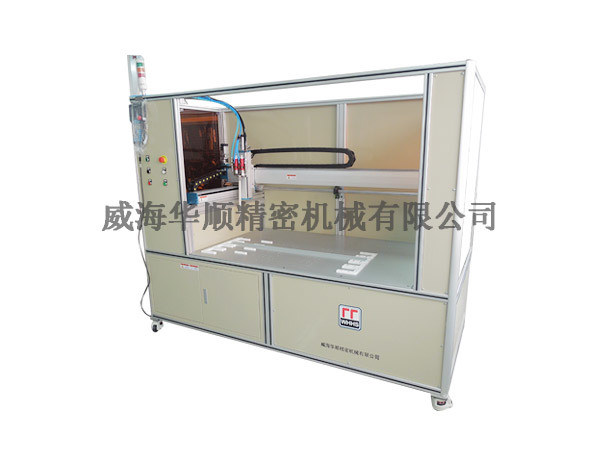

It is obviously different from the ordinary single-component glue pouring machine. AB glue machine is a glue pouring machine specially used for point two-component catalytic glue. As we all know, two-component glue is a kind of glue that needs to be cured after mixing the glue and the catalyst. AB glue machine is developed for this kind of glue. It has two glue barrels, of which barrel A is used to hold this glue and barrel B is used to hold catalyst.

The glue is automatically mixed by the machine. Since the glue is respectively installed in the AB two barrels of the AB glue machine, the glue is pumped into the mixing tube through the pump and mixed before being ordered, so there is no need to worry about the glue solidifying in the barrel. Common AB glue machines on the market include full-automatic double-liquid glue filling machine with XYZ manipulator and AB double-liquid glue filling machine without manipulator.

The common AB glue machines on the market have AB double-liquid glue filling machines with two pumps. Different pumps are used for different glues. The commonly used two-component catalytic glues include "AB epoxy resin", "AB polyurethane", "AB silicone", "PU glue", etc.

The AB glue machine using the gear pump is suitable for glue that does not contain filler, that is, in order to enhance the thermal conductivity of the glue, the glue is filled with granular substances with strong hardness such as alumina, quartz sand, ceramics, etc. When the gear pump of AB glue machine encounters glue containing filler, it is easy to wear over time, resulting in inaccurate glue output, resulting in long-term non-drying of the products and increasing the proportion of defective products.

The use of screw pump AB glue machine relative to the gear pump, higher wear resistance, more suitable for filler glue. In the process of using AB glue machine, we must consider the amount of glue produced each time. For example, the product you want is 1g and the glue ratio is 10:1, which is equivalent to the minimum amount of glue produced by B glue reaching 0.1g. Therefore, we must consider the amount of glue produced by the product and whether it can meet the dispensing requirements.

More information

Dry goods sharing, one minute to take you to understand ro film rolling machine

2023-02-09

Introduction of ro film stacking machine?

2023-03-03

The use of ro film stacking machine?

2023-03-14