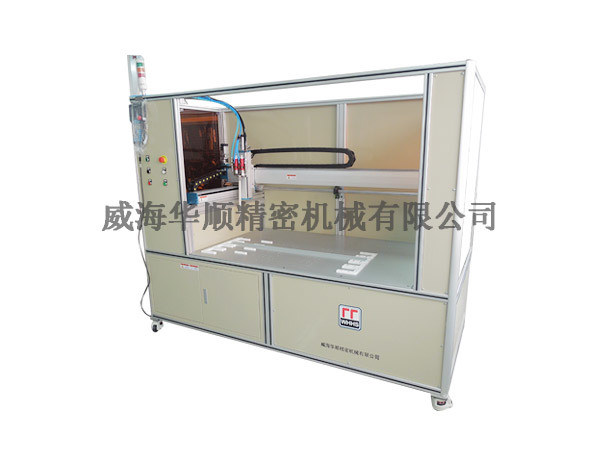

Take you to understand the operating procedures of the automatic industrial film rolling machine

2023-05-06

With the continuous development of the economy, automatic industrial film rolling machine has been applied to all walks of life, saving production costs for large and small enterprises. However, many friends are not very familiar with the operating procedures of the automatic film packaging machine, and various problems will occur in the process of use.

The following is a detailed introduction to the operation process of industrial film rolling machine.

Wear PPE correctly before going to work. Before starting up, check the filling mechanism of the roll film packaging machine, observe the activities of each moving part, and check whether the actions of each mechanism are coordinated. Before starting the roll film packaging machine, you must first know the quantity of materials in the intermediate warehouse. Only when the materials are fed to the specified material level can it be started. Before starting up, check the gas pipeline for gas leakage and material leakage, observe the pressure gauge in the gas pipeline, and start up after the air pressure reaches the set pressure. Before starting the roll film packaging machine, observe the surrounding environment and remove all obstacles. When the packaging machine is just started, it should be idle for several weeks, observe the operation, and then start packaging. Pay attention when inserting the bag, insert the paper bag into the rotating outlet quickly and accurately, and do not leak the bag. In order to ensure that the weight of cement bagged at the factory meets the requirements, the sampling inspection and calibration inspection of cement bags shall be carried out at the specified time. Wear labor protection articles correctly when going to work, and do not drink alcohol four hours before going to work. Post personnel shall be familiar with sound and light signals such as startup alarm, production alarm, fire alarm and call signal. Do not walk on or across the equipment.

It is strictly forbidden to rest near the running equipment of the industrial film rolling machine. Safety signs are clear and complete. Field lighting shall be normal during production. Keep the workshop clean and protect the mechanical and electrical equipment. Make sure that the shaft has a sleeve, the wheels have a cover, the ditch has a cover, and the platform and stairs have railings. Workplace for easy to fall, tripping potholes, obstacles, to properly handle or hang signs according to the need to regularly roll film packaging machine troubleshooting. When overhauling the roll film packaging machine, it is necessary to prevent the roll film packaging machine from starting suddenly. What needs to be understood is that the emergency stop switch simply cuts off the power supply or the motor starter. To be sure, the device should be cut. Turn on the power switch on the switchboard and affix the service sign.

The industrial film winding machine should be checked and confirmed before starting, and relevant personnel should be contacted, and the equipment should be started when conditions permit. When the mill, warehouse and dust collector are overhauled, the manhole door shall be guarded. Low-voltage lighting power supply below 36V shall be used for internal operation of plant, warehouse, pipeline, etc. In order to prevent leakage of electrical equipment, it should be checked whether it is grounded or grounded. The workshop should be kept clean and tidy to prevent dust and grease from accumulating or leaking. The above is the operation process of the automatic film packaging machine. Do not underestimate the operation process of the automatic film packaging machine. Correct and reasonable operation can greatly improve the service life of the roll film packaging machine.

More information

Dry goods sharing, one minute to take you to understand ro film rolling machine

2023-02-09

Introduction of ro film stacking machine?

2023-03-03

The use of ro film stacking machine?

2023-03-14